Drilling Fluid Solids Control Equipment Manufacturer

2018-01-24

KOSUN is specialized in drilling mud solids control equipment manufacturing in China since 1992. We have rich experience in solids control system design.

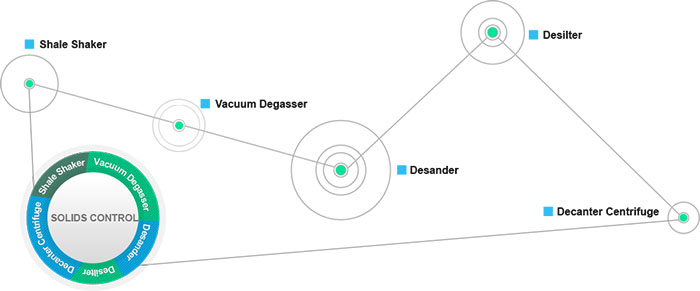

Five-stage solids control equipment,including Shale Shaker,Vacuum Degasser,Desilter and Decanter Centrifuge,ensures clean mud recycling and mud can be reused.

SHALE SHAKER

Shale Shaker is used as the first stage equipment for drilling mud solids control equipment. It can remove 74μm or above size particle from mud.

Features & Benefits of Shale Shaker:

1.High G-force linear motion up to 7.4G

(adjustable according to work requirement).

2.Deck adjustment while drilling patented technique AWD

(adjust 0.5°/time,from -1°~5°)mechanical mode, to ensure safe operation.

3.Weir design feed inlet port, steady mud delivery,reducing abrasion for shaker screen.

4.Smaller size motor and lower position deck, making sure lighter participating vibration weight, getting bigger treatment capacity.

5.Splash proof cover for deck, keeping the machine cleaner.

6.Easy screen replacement with hook fixed design.

7.Link Bolts: SS304 Material.

8.Explosion Proof motor.

9.API Q1&ISO Certified Manufacturer.

VACUUM DEGASSER

Vacuum Degasser separates H2S and other gases. It is helpful for reducing cone part abrasion on desander and desilter during further handling.

Features & Benefits of Vacuum Degasser:

1.Self-suction device.

2.High efficiency separating gas from drilling fluid.

3.Compact design, occupy smaller space.

4.Can be also used as mud agitator with big power.

5.Explosion Proof motor.

6.API Q1&ISO Certified Manufacturer.

DESANDER

KOSUN Desander is used for separating 45-74μm particle from mud.

Features & Benefits of Desander:

1.Clamp and replaceable cone design, flexible cone number for option

(1pc to 3pc,dia 10″ or 12″).

2.Good wear resistance for cone material with PU and high-chromium iron for option.

3.Smaller size motor and lower position deck, making sure lighter participating vibration weight, getting bigger treatment capacity.

4.Compact design, occupy smaller space.

5.Easy maintenance.

6.Explosion Proof motor.

7.API Q1&ISO Certified Manufacturer.

DESILTER

KOSUN Desilter is used as 4th stage equipment for drilling fluid solids control system.It separates 15-44μm particle.

Features & Benefits of Desilter:

1.Clamp and replaceable cone design,flexible cone number for option(8pc, 10pc, 12pc, 16pc, 20pc, dia 4″ or 5″).

2.Longer work life for cone with 100% polyurethane(PU) material.

3.Smaller size motor and lower position deck, making sure lighter participating vibration weight, getting bigger treatment capacity.

4.Compact design, occupy smaller space.

5.Easy maintenance.

6.Explosion Proof motor.

7.API Q1&ISO Certified Manufacturer.

DECANTER CENTRIFUGE

KOSUN DC Series Decanter Centrifuge is used for separating tiny particle(dia≥2μm). The proportion and viscosity for the recycled mud can satisfy different mud handling requirement according to the drilling condition.

Features & Benefits of Decanter Centrifuge:

1.High quality stainless steel material for cone and impeller part,guarantee a longer work life for the machine.

2.Link Bolts: SS304 Material.

3.Strict manufacturing technique, dynamic balance accuracy inspection has been done for all rotary parts separately.

4.Rotary balance adjustment will be done after the assembling,guarantee safe work circumstance.

5.Use Electronics & Electric component design for overcurrent protection, to ensure safe operation and easy maintenance.

6.Easy for adjusting the mud treatment condition and water content of the solids according to the work request.

7.Coating & Painting: (Kansai & Cosco)Japan Brand epoxy zinc-rich anticorrosive paint and heavy anticorrosive painting, heat treatment for the entire machine.

8.All Motors are Explosion Proof.

9.API&ISO Certified Manufacturer.

News

- 07-11Technical features of using KOSUN drilling waste mud treatment system

- 07-07Main equipment of solids control system in drilling

- 06-26Geothermal well mud treatment system manufacturer—KOSUN solid control

- 06-26The key to achieving mud zero discharge is on-site processing after solid-liquid separation

- 05-10Application Scenarios of KOSUN Drilling Waste Treatment Equipment

- 05-10Environmental protection new regulations require to achieve zero discharge of drilling waste

- 05-09KOSUN Solid-liquid Separation Equipment is used in the construction industry

- 04-19What are the main functions of the Mud Agitator during use?

- 04-15The Advantages of KOSUN's trenchless horizontal directional crossing mud recovery system

- 03-15Vacuum degasser is mainly divided into centrifugal degasser and jet degasser